Lesson 5: The life cycle of a product

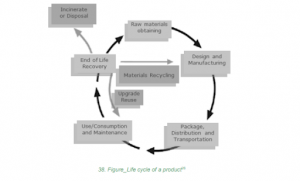

In this lesson, we will explore the various stages in the life cycle of a product, from its creation to its end-of-life.

- Introduction to the Product Life Cycle

- Products go through a series of interconnected stages that can have environmental impacts. These stages, known as the product life cycle, encompass five phases according to ISO 14040: 1997. We will explore each phase in detail.

- Raw Materials Phase

- Raw materials are obtained through extraction or harvesting, such as converting bauxite to aluminum or oil to plastic. This phase also involves energy consumption and land transformation.

- Manufacturing Phase

- During manufacturing, materials are transformed into products through specific processes like casting and thermoforming. Additional materials and energy are used in this phase, including machine tools and lighting.

- Distribution Phase (Transportation and Packaging)

- Products are packaged and transported from manufacturers to consumers. Different modes of transport have varying energy consumption and emissions. Consideration of supply chain transport is essential.

- Use Phase

- During this phase, products are used, and maintenance and repairs may extend their lifespan. Environmental impacts at this stage include energy consumption, maintenance requirements, and user behavior.

- Maintenance and Repair Services

- Maintenance and repair services can prolong a product’s life. Parts and components may be repaired or upgraded to improve functionality. This phase aims to reduce waste and promote product longevity.

- End-of-Life (EoL) Phase

- When a product can no longer be used, it reaches the end-of-life phase. EoL management options include disassembly, reuse, remanufacture, recycling, incineration, or landfill.

- Waste Management and Recycling

- Waste management priorities should include durability, upgradeability, reuse, recycling, energy recovery, and proper disposal. Recycling involves restoring useful materials from discarded products.

- Remanufacture and Reprocessing

- In the remanufacture cycle, products are disassembled, inspected, and repaired. Parts are returned to their original use or recycled. This phase promotes product reusability.

- Recyclability

- Recyclability is determined by several factors, including whether recycling is the best option, the environmental impact of recycling, design for disassembly, and material identification.

- Closed-Loop and Open-Loop Recycling

- Recycling can take place within a closed-loop system, where materials are recycled back into the same product system, or in an open-loop system, where materials are used in different product systems.

Conclusion

- Understanding the product life cycle and its environmental implications is crucial for designing sustainable products. Designers and industries must prioritize materials, processes, and recycling practices that minimize environmental harm.

In this lesson, we’ve examined the life cycle of a product, from the extraction of raw materials to its end-of-life phase. Recognizing the importance of sustainable design and waste management practices is essential for reducing the environmental impact of products.