5 ways EU scientists are making batteries better, safer, and greener

Scientists at the Joint Research Centre (JRC) perform cutting-edge research for finding ways to produce better batteries and to recycle them.

Batteries are central to both the green and the digital transitions.

By storing more energy in batteries when the wind is blowing and the sun is shining, we could ensure that supply meets the energy demand without relying on non-renewable energy sources such as gas or oil.

Our phones and laptops, just as many other mobile digital devices, rely on batteries, making them vital for the digital transition.

European consumers expect all batteries sold in the EU to be safe, sustainable, and perform according to the product specification. You do not want your car’s battery to catch fire, or to run out of electricity after 100 km if its range should be 500.

The European Commission’s proposal for a new Batteries Regulation aims to ensure that batteries are long-lasting and safe. This Regulation will apply to all batteries, except those connected with the essential security interests of EU countries or batteries used in equipment designed to be sent into space.

It specifies that necessary raw materials need to be sourced in full respect of human rights and that batteries shall be produced with the lowest possible environmental impact. At the end of their consumer-life, batteries need to be collected to be either repurposed, remanufactured or recycled, feeding valuable components and materials back into the economy.

The Regulation also proposes a ‘battery passport’, which would apply to all industrial and electric vehicles with a capacity higher than 2 kWh. Accessible online, the passport will be an electronic record for each battery, containing information about the basic characteristics of the battery type and model. It will store information related to performance and durability parameters, and note any changes to the status of the battery.

The proposed Regulation is closely linked with the Commission’s wider efforts for a Sustainable Product Framework, in particular with the Eco-design for Sustainable Products Regulation. This aims to introduce rules on performance and information requirements for greener products, waste prevention and reduction, destruction of unsold goods, green public procurement and the digital product passport.

Scientists at the European Commission’s Joint Research Centre (JRC) support this policy with research to ensure the monitoring and reduction of the environmental footprint of batteries, make them safer, better-performing and more durable, as well as replaceable and widely recycled. Let’s take a look at each of these aspects.

More environmentally-friendly batteries

The expected massive use of batteries should reduce carbon emissions, but to maximise this potential their overall life cycle must have a low carbon footprint.

The battery life cycle is currently energy- and material-intensive and therefore associated with significant environmental impacts, mainly due to the greenhouse gas emissions from raw materials sourcing and refining.

To address this, the Batteries Regulation proposal foresees, among other measures, the mandatory declaration of the carbon footprint of batteries put into the EU market; the creation of carbon footprint classes (similarly to the scheme used for energy labelling of appliances); and later on the setting of maximum carbon footprint thresholds for batteries entering the EU market.

The carbon footprint of batteries has to be calculated based on the Product Environmental Footprint (PEF), a lifecycle-based method that the JRC has been developing since 2010 and recently adopted in the Recommendations of the European Commission. Currently, the JRC is tailoring PEF Category Rules developed by industries, adapting to the ambition of the battery Regulation.

The JRC aims to develop clear rules and high-quality data that would allow a robust assessment and comparability of the carbon footprint of batteries. A lower carbon footprint will become a competitive advantage for battery manufacturers while promoting an overall reduction of greenhouse gas emissions.

The declaration of the carbon footprint of batteries is a first-of-a-kind approach in European and worldwide product policies. It is expected that this will be followed by similar applications to other key and carbon-intensive products in the future.

Safer batteries

The JRC team analysed existing battery safety laws and testing procedures so that they could address gaps in regulations. One of these gaps relates to thermal propagation. Severe failure in one component of a battery can spread to neighbouring components and finally consume the whole battery. This causes the release of toxic gases and often of fire.

The team are developing a new test based on JRC research on the many ways such a reaction could be triggered. The test considers many real-life scenarios and risks to test the procedure in batteries and vehicles in realistic conditions. Once the process is validated in experiments, the JRC will propose that it becomes part of the legislation.

In 2018 already, JRC researchers’ work on assessing the toxicity of battery electrolytes resulted in a new global legal requirement for electric vehicle safety.

Batteries that last longer

In the radio clock next to your bed or the smoke detector in your living room, you want a battery that can continuously supply the low power needed to run the device, so it can operate for months without a need to replace or recharge the battery. In a mobile phone or electric vehicle, in contrast, you want a battery that can provide higher power if needed and that can be quickly recharged. For different applications, “high performance” can mean something very different.

Regarding durability, a life span of three years might be fine for a battery used to run a mobile phone, but who would buy an electric car where the battery needs to be replaced after just a few years?

The New Batteries Regulation aims at removing low-performing batteries from the EU market. In-order to identify these batteries, parameters characterising the performance and durability of batteries need to be carefully chosen and minimum requirements need to be set.

In close cooperation with the European standardization organizations CEN and CENELEC, the JRC supports the identification of such parameters. In a second step, the JRC will support the other Commission services with setting minimum requirements.

Recovering and reusing valuable materials

Critical materials and components needed for batteries include primary raw materials such as cobalt, natural graphite, lithium, manganese and nickel.

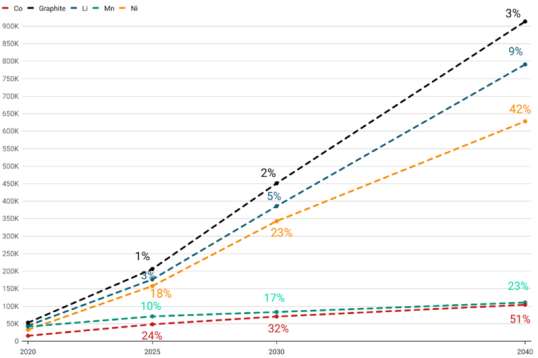

According to JRC data, the global demand for raw materials for batteries is expected to grow at an unprecedented rate: for example nickel, graphite and lithium, are projected to increase in 2040 by 20, 19 and 14 times, respectively, compared to 2020.

The EU will continue to be heavily dependent on imports of key primary and refined materials, including from countries with poor governance and/or with proven violations of human rights. For the EU’s strategic autonomy, it is necessary to decrease its dependence on material imports, in particular by promoting the adoption of more circular and resource-efficient batteries.

The EU has a long experience of waste collection and treatment, and its collection and recycling infrastructures are particularly well developed. The enhancement of Circular Economy strategies(reuse, repurposing, remanufacturing, recycling) can hence contribute to decreasing the dependency of the EU for raw materials (see figure for the potential contribution of recycling).

Estimated consumption of battery raw materials [t] and supply potential from secondary raw materials (old+new scrap) [%] in the EU (2020-2040)

Source: https://joint-research-centre.ec.europa.eu

Published by CVTI