Lesson 6: Methods that meet today’s requirements – surface reinforcement

In this lesson, we will delve into Surface Reinforcement by Open Arc Welding and the Repair of Special Parts Using Special Welding Procedures.

- SURFACE REINFORCEMENT BY OPEN ARC WELDING

Introduction

- Surface reinforcement involves applying a hard, abrasion-resistant layer to protect the base surface.

- This technique is highly effective in extending the lifespan of various components.

Tools and Materials

- Tubular wire with specific functions like arc stabilization, deoxidization, fluidization, carbide forming, and additives for desired properties.

- Common diameter range: 2-4 mm (e.g., 2.8 mm).

- Applications include low carbon, non-alloyed, Mn, Mn-Cr alloy structural steels, and more.

Process

- Surface preparation involves cleaning and defect type assessment.

- Rounding edges and corners and marking crack traces.

- Application of the tubular wire to create a hard, abrasion-resistant layer.

- Considerations for specific material compositions and requirements.

Applications

- Ideal for reinforcing low carbon and alloyed structural steels.

- Butt and fill-up welding of medium carbon alloy steels.

- Suitable for forming stainless steel surfaces (Cr, Mn, Ni).

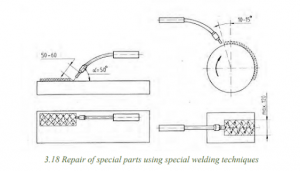

- REPAIR OF SPECIAL PARTS USING SPECIAL WELDING PROCEDURES

Machine Frames, Frame Structures, Leaf Springs

- Common failures include cracking, fracture, and embrittlement.

- Risk of indentation or annealing during welding due to material composition.

- Recommended hardness test in the weld area before reuse.

Welding Technology

- Direct current with positive polarity.

- Electrode materials with high Cr, Ni, and Mn content for adequate elasticity and tensile strength.

- Target tensile strength of the weld: 800-850 MPa.

Minor Chipping, Fracture of Pinions, Sprockets, Rib Shafts

- Components subjected to frequent and unpredictable conditions.

- Preheating to 500-600°C required before welding.

- Use of a fluxing agent for proper flaw space filling.

- Selection of welding rod characteristics: Cr, Ni, Si alloys, low melting point, high hardness.

Highly Stressed Cutting Edges for Machine Tools

- Carbide filling and sharpening methods.

- Suitable welding processes and bonding methods.

- Deposition of materials with excellent abrasion resistance, containing metal carbides, nitrides, and borides.

Self-Sharpening Concept

- The concept explained in the context of carbide charging, ensuring the effectiveness and longevity of tool surfaces.

Coated-Electrode Manual Arc Welding

- Performed with direct current and bonded with positive polarity.

- Preparation steps include removing previous armor, preheating, and applying a flexible pad layer if needed.

Conclusion

- Surface reinforcement and special welding procedures are essential in prolonging the life of components subjected to harsh conditions.

- Understanding these methods is crucial for professionals involved in the maintenance and repair of specialized parts.