Lesson 4: Methods that meet today’s requirements – hot metal powder coating

In this lesson, we will delve into a method that aligns with contemporary requirements for effective repairs and renovations – Hot Metal Powder Coating.

Introduction

- Meeting today’s requirements for efficient repair and renovation often necessitates innovative methods.

- Hot metal powder coating offers a unique solution with distinct advantages over other techniques.

Hot Metal Powder Coating

- Overview

- The technological process of hot metal powder coating shares similarities with cold powder spraying but results in significantly different technical parameters.

- The crucial difference lies in the post-application heating of the coating to temperatures between 950-1000°C.

- This process eliminates porosity, forming a continuous solid layer.

- The heated material diffuses into the component’s surface without mixing due to differing melting points, creating a diffusion bond.

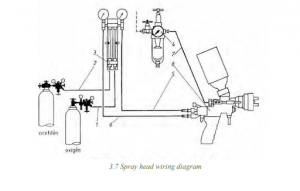

- Procedure

- The steps of hot metal spraying include preparation, cleaning, defect type determination, pre-machining (if necessary), surface preheating, even application of alloy powder (up to 0.2 mm in one step), flame fusing of the topcoat at 950-1000°C, and cooling in air.

- A chipping allowance before fusing is increased by 30% to account for expected shrinkage.

- A minimum cover layer of 0.25-0.3 mm is desirable after finishing.

- Characteristics

- The applied layer typically exhibits a hardness of 18-65 HRC without heat treatment.

- It demonstrates excellent resistance to dynamic abrasive wear and corrosion.

- It is unsuitable for use on shafts thicker than 35-40 mm due to intense heat ablation.

- In some cases, melting may alter the fabric structure of the base material, potentially leading to a loss of strength.

- Applications

- Hot metal powder coating finds applications in various components such as needle roller bearing seats, water pump shafts, valve discs, valve seats, turbocompressor shafts, switch forks side faces, and camshaft cams.

Conclusion

- Hot metal powder coating is a method that meets modern requirements for effective repairs and renovations.

- Its unique characteristics, including diffusion bonding, corrosion resistance, and excellent wear resistance, make it a valuable addition to maintenance practices.

- While it has limitations, it offers a reliable solution for specific applications.