Lesson 2: Classic methods of component repair and overhaul

In this lesson, we will explore classic methods used for repairing and overhauling components. These methods are essential for economical individual or small series repairs, making them a fundamental aspect of maintenance.

Introduction

- Classic repair methods play a crucial role in extending the lifespan of components, especially in scenarios where individual or small series repairs are economically viable.

- In the past, large-scale refurbishment plants were prevalent, but modern approaches prioritize resource efficiency and sustainability.

Classic Repair Methods

- Polishing

- Ideal for addressing minor surface defects.

- Common applications include shroud surfaces under seals and hydraulic power cylinder shrouds.

- Parts remain interchangeable with their original size after polishing.

- Grinding is mainly used to form seals on tapered mating surfaces, for example during engine cylinder head overhauls, valve and valve seat rebuilds

- Machining to Repair Dimensions

- The oldest and simplest method involving machining the component to restore its dimensions.

- Requires sufficient material reserves at the location to be repaired.

- Used for shaping pins, holes, or fitting surfaces to a specified size.

- Plasticizing

- Applied to structural steels and non-ferrous metals.

- Used for reconditioning parts by sealing or stretching the material.

- Forming can be done through cold or hot pressing.

- Examples include radial pressing of a valve plate.

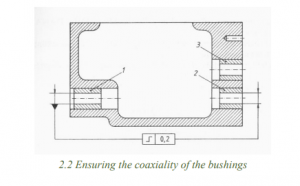

- Shelling

- Commonly used to increase the size of worn bores or shaft diameters.

- Internal bushings are often made from materials matching the original.

- Bushings are solidly fitted, and bore size matches the original.

- Non-ferrous metal bushings can sometimes be replaced with plastics, but size adjustments are necessary due to their properties.

- Electroplating

- Primarily involves hard chromium plating.

- Used to coat lightly worn but finely fitted parts to a thickness of 0.2-0.3 mm.

- Effective for parts originally chromium plated.

- Key properties of the chrome layer include high hardness, wear resistance, corrosion resistance, and heat resistance up to 500°C.

- Economical for large series but less significant in modern repair practices.

Conclusion

- Classic repair methods are essential for economical individual or small series repairs.

- These methods include polishing, grinding, machining to repair dimensions, plasticizing, shelling, and electroplating.

- Understanding these methods is crucial for maintenance professionals to make informed decisions about component repair and overhaul.

Read the textbook from page 6-22. You can find the textbooks’s content on this link.