Lesson 4 – the technical condition of the machinery

In this lesson, we will delve into the essential aspects of determining and evaluating the technical condition of machinery, including parameters, diagnostics, wear reserves, and margin of error.

Understanding Technical Condition and Function

- Determining and inspecting the technical condition of machinery is vital in maintenance.

- Technical condition comprises various characteristics like performance, efficiency, energy usage, quality of work, ergonomics, and maintenance.

- Parameters defining the prescribed condition are essential for specific machinery as per standards and manuals.

Functionality vs. Prescriptive State

- Functionality refers to fulfilling a purpose efficiently, which might not always require meeting all prescribed parameters.

- Some tasks may function well with lower parameter levels than those specified.

- The key is ensuring the machine’s ability to perform required functions.

Complex Systems and Elements

- Machinery is complex and can be seen as interconnected elements forming a system.

- Elements within this system have independent input and output parameters.

- Different modes of operation, efficiencies, and time-dependent characteristics are integral to machinery.

Importance of Time-Dependent State Variables

- Time-dependent state variables are crucial for maintenance.

- These variables help create an n-dimensional state space representing the system’s condition.

- Variables that remain constant or change negligibly are considered secondary in maintenance.

Condition Determination and Diagnostics

- Understanding a machine’s operating principle, construction, and characteristics is vital for assessing its proper functioning.

- Deviations from normal operating characteristics, such as unusual noises or changes in power consumption, may indicate faults.

- Diagnostics involve non-disruptive monitoring and adjustment to maintain desired operating characteristics.

Detecting Faults with Senses and Instruments

- Skilled technicians can often detect faults using their senses.

- Visible issues like loose joints or external cracks are easier to spot.

- Audible signs, touch, and smell can also provide clues about machine condition.

- Instrumentation, like built-in sensors, helps monitor critical parameters and diagnose faults.

Instrumental Methods for Fault Detection

- Techniques like thermography, spectroscopic oil analysis, particle count tests, and ferrography aid in fault detection.

- Vibration and noise monitoring with sensors and microphones are crucial for identifying issues.

- Monitoring parameters like temperature and emissions helps assess machinery health.

Maintenance Characteristics

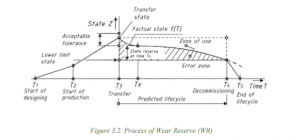

Wear Reserve

- Functional performance occurs during operation, with the machine wearing down as needed.

- Wear and tear can vary widely in duration and intensity.

- The wear reserve (WR) represents the machine’s use value to the user and is essential for determining maintenance needs.

- The WR can be expressed as a percentage of the initial value.

Margin of Error

- Knowing the failure limit and remaining service life is vital for maintenance.

- The maintainer seeks a relationship between the WR and the remaining hours or output.

- Understanding the utilisation and depletion reserves helps plan maintenance effectively.

Conclusion

- Evaluating the technical condition of machinery involves considering various parameters and characteristics.

- Maintenance professionals use their senses, instrumentation, and diagnostic techniques to identify faults.

- Understanding wear reserves and margin of error is crucial for effective maintenance planning.

Read the textbook from the 24th page. You can find the textbooks’s content on this link.