Lesson 1 – Workpiece locating and locating devices

Read the textbook from the 1st page. You can find the textbooks’s content on this link.

1. THE ROLE OF MACHINERY FIXTURES

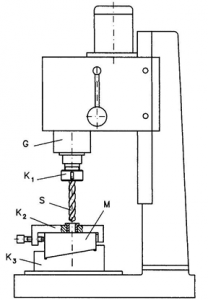

The components are machined in a machining system consisting of the workpiece, the fixture, the machine tool and the tool (Figure 1-1.). Fixtures are defined as equipment which, in addition to the machine tool and the tool, is required during the mechanical machining, are needed in carrying out the operations but that are not directly involved in the shaping of the workpiece.

DEPENDING ON THEIR ROLE, FIXTURES CAN BE:

_tool holders

_drill jigs

_workpiece holder fixtures

The TOOL HOLDERS (K1) establish a link between the main spindle, the tool holder and the tool shank of the machine tool. The tool shanks and connecting parts as well as the spindle ends and tool holders are standardized and therefore the tool holders can be purchased commercially or from specialised companies. During the planning, the task usually comes down to selecting the right fixture.

DRILL JIGS (K2) are used on conventional drilling machines but often the tool guide is part of the workpiece holder fixture. Modern NC controlled machines do not require tool guide because the exact location of the bores is ensured by the control and the movement system of the machine tool.

1-1. Figure The symbolic representation of the role of the fixture

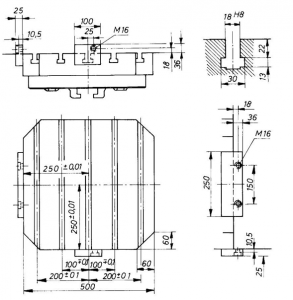

THE WORKPIECE HOLDER fixtures or, in short, holder fixtures (K3) create a connection between the workpiece and the machine tool (machine table or the main spindle on lathe machines). The variety of workpieces is basically limitless. This wide variety of workpieces should be ’fitted’ to a machine table of a given design. It is clear that it cannot be achieved by direct connection, so a ’mechanical interface’ should be placed between the machine table and the workpiece. This role is carried out by the holder fixture. The symbolic representation of this role is shown in Figure 1-2. As an example the machine table design and measurements of the machining centre ’MAKINO MC65’ are shown in Figure 1-3.

Due to the variety of workpieces, in most cases, the holder fixture should be designed separately for each workpiece and for each operation of the manufacturing process. The knowledge required to solve this task is presented and discussed below.

The basic function of a holder fixture is to locate and clamp the workpiece (sometimes also to guide the tool).

1-3. Figure The symbolic representat ion of the role of the fixture

1-3. Figure The symbolic representat ion of the role of the fixture

1-2. Figure The machine table of the machining centre „MAKINO MC65”

1-2. Figure The machine table of the machining centre „MAKINO MC65”