Lesson 2: Example of requirement: maximum wheel torque

Introduction:

- We will explore a use case surrounding passenger car powertrain development.

- Our focus: “Maximum Wheel Torque” requirement.

Setting the Scene:

- A vehicle manufacturer (OEM) is developing a Battery Electric Vehicle (BEV) for the European market.

- Drawing from prior experience with combustion vehicles, they have preliminary specifications and understand the needs of drivers, passengers, and legislations.

Initial Requirements:

- Car tire size: 205/55 R16.

- The vehicle will have front-wheel drive only.

- The car must achieve maximum torque and power of 100 kW momentarily at 90 km/h.

Deriving the Wheel Torque Requirement:

- Engineers determined that the powertrain must deliver a total torque of 1260 Nm.

- This translates to 630 Nm for each front wheel.

Calculating Motor Torque:

- To determine the torque needed from the e-motor, consider the system’s components.

- The OEM decides to repurpose the differential from its combustion vehicles.

- Using a stock reduction gear set, the complete reduction ratio from e-motor to wheel is established at 11.63.

- Therefore, the e-motor’s torque requirement can be deduced.

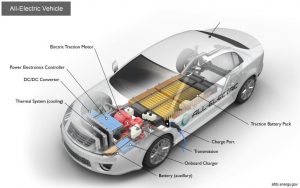

Figure Layout of a Battery Electric Vehicle (BEV)

Validation and Verification:

- E-Motor Testing:

- The e-motor is installed on a test bed, powered by an ideal electrical source, and linked to a dynamometer to regulate speed.

- The dynamometer sets the speed, and the motor’s torque is measured. For our case, assume it met the needed torque.

- Inverter Testing:

- The inverter’s role is to supply current to the e-motor.

- It’s tested under various conditions, using passive or active electrical loads.

- Active loads, like e-motor emulators, can mimic an e-motor’s realistic behavior.

- Successful tests confirm component-level requirement fulfillment.

Integration Process:

- The task now is to integrate the inverter and e-motor.

- This involves “teaching” the inverter to drive the e-motor under various conditions, such as:

- Varying driver inputs.

- Different driving scenarios.

- Changing environmental conditions.

- Interactions with other powertrain components.

- Integration ensures consistent performance within specified tolerances, leading to a uniform user experience and compliance with standards.

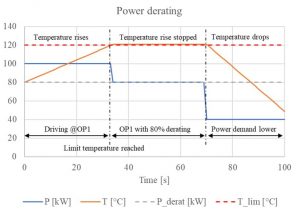

Figure Example of a simple derating strategy allowing the maximum possible power e.g. during an acceleration period

Integration Testing:

- Utilizing both measurements and simulation tools, the e-motor’s performance is characterized.

- Simulations, if mature and validated, can sometimes replace certain testing phases.

- The purpose: Cover all operation conditions, such as:

- Battery voltage ranges.

- Cooling scenarios.

- Thermal conditions.

- Successful tests result in an integrated system, with the inverter able to accurately drive the e-motor.

Advanced Integration:

- Progressing up the V model, the next step involves integrating the e-drive with the gearbox and differential.

- Modern powertrains are becoming increasingly integrated, making individual component validation challenging.

- Example: A shared cooling circuit for the gearbox and motor, necessitating special samples for component testing.

Conclusion:

- “Maximum Wheel Torque” is an essential requirement in BEV design, impacting various components.

- Ensuring each component meets its requirement and then successfully integrating them is pivotal to achieving the desired vehicle performance.