Lesson 10 – CASE STUDY – APPLYING CIRCULAR ECONOMY PRINCIPLES TO THE TIRE INDUSTRY

The concept of 3R (Reduce, Reuse, Recycle) tried to develop responsible consumption habits. However, the growth of ecological thinking has given rise to four new Rs in addition to these basic 3Rs; the 7 R’s today (Reduce, Reuse, Recycle, Redesign, Renew, Repair and Recover) which refer to the actions needed to facilitate and accelerate the transition to a circular economy in the tire industry.

Redesign

The starting point of the circular economy is based on the redesign of the products and services themselves, taking into account the environmental consequences. The main objective of these models has so far been focused on aspects leading to the reduction of fuel consumption and, consequently, polluting emissions, while maintaining road safety.

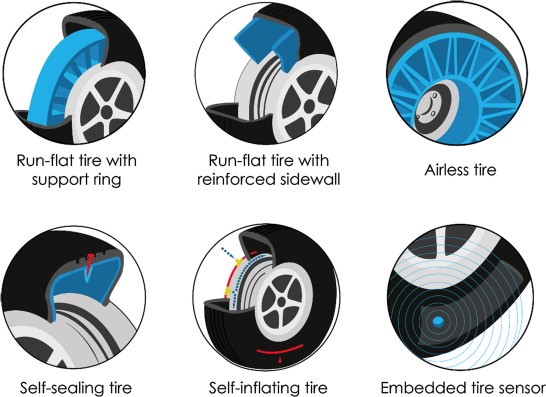

Some examples of new tire concepts are shown in Figure 1.

Figure 1. Innovative tire concepts and designs [ [i]]

The next challenge is to reduce tire design to individual components or elements to facilitate tire repair or disassembly and reuse. These new models have resulted in innovative products, some of which are already on the market.

Renewal – Manufacturing tires from resources regenerator

The objective of manufacturing tires from renewable resources is to achieve sustainability but also to reduce dependence on fossil fuels. Natural rubber has unique properties of strengthening, resistance to tearing, impact and abrasion, among others.

Reduction

Downsizing is the optimal use of materials, and the tire industry primarily aims to reduce the weight of tires to reduce overall vehicle weight as well as to achieve fuel economy.

Reuse

Reuse includes the sale of partially used tires for domestic road use and other purposes, as well as for export to other countries where the road use conditions are less restrictive.

Repair

Repair is part of the principles of the circular economy that contributes to extending the life of products, allows savings in raw materials and energy and helps to reduce waste.

Tires can be repaired in many cases, for example, when they are deflated, for various reasons: puncture, loss of pressure, when the affected part is on the tread of the tire.

Recovery

Recovery: transforms a waste into energy or fuel, which can be reintegrated into the economic flow as a substitute resource for the use of other energy sources.Energy and material recovery offers a complementary alternative to address tire waste issues and achieve sustainable development goals following the principles of the circular economy.

Tire pyrolysis

Pyrolysis consists in the thermo-chemical decomposition (400–1200 0 C) of organic compounds in low molecular weight products at reduced or normal pressure and under an inert atmosphere, preventing oxidation and changes in phase or chemical composition.

Recovery energy

The fuel derived from tires (Tire derived fuel TDF), one of the main options for ELT, is mainly used in cement kilns, but also in thermal power plants, pulp and paper mills, steel mills and industrial boilers. In Europe, the cement sector is the main use of TDF.

Recycle

Recycling is keeping resources in the loop for as long as possible. It transforms a waste into a material that can be reintegrated into the economic stream as a substitute resource for the use of virgin resources. Tire recycling is defined as any material recovery operation of used tires, namely cutting, shredding, granulating, or any other operation that causes changes in the nature or composition of the used tire, through industrial processes, in order to obtain raw materials.

[ [i]] Amick, Sarah, Sustainability: A driving force for the US tire manufacturing industry’, US Tire Manufacturers Association. 2018., https://www.ustires.org/sustainability-driving-force-us-tire-manufacturing-industry.