Lesson 2 Designing vehicles using renewable resources for waste-reducing

Designing vehicles using renewable resources for waste-reducing

The automobile industry is doing a remarkable job in developing renewable resources. These resources aim to lower the amount of petroleum used for production. As a result, there’s a reduced carbon footprint. For now, renewable materials are suitable for designing passenger seats of vehicles. However, there are ongoing experiments aimed at in-cooperating renewable resources vehicle’s design.

Renewable, plant-based materials are also part of FORD sustainability strategy. Ford is using nine plant-based materials in current and past vehicle production. Ford industry-first sustainable materials include soy foam, wheat straw, rice hulls, tree-based cellulose, and coffee chaff.

Soy seat cushions, backs and headrests were one of many Ford firsts. They have been used in every Ford North American built vehicle for more than a decade, over 18.5 million vehicles. Bio-based foams have reduced greenhouse gas emissions by over 228 million pounds, and use of soy foam, launched on Mustang and now on all American vehicles, has helped save 5 million pounds of petroleum annually since 2008. Ford Advanced Polymer Technologies team continues to pioneer the development of new sustainable plastic materials including using waste from olive production to reinforce plastics, captured carbon dioxide in plastic formulation and polymer resins made from renewable feed stocks. For example, it is tested whether the tree-based cellulose composites, that were incorporated into Lincoln Continental consoles, can be used in other applications. Ford experts are also deriving value from waste material, using recycled ocean plastics in the Bronco Sport.

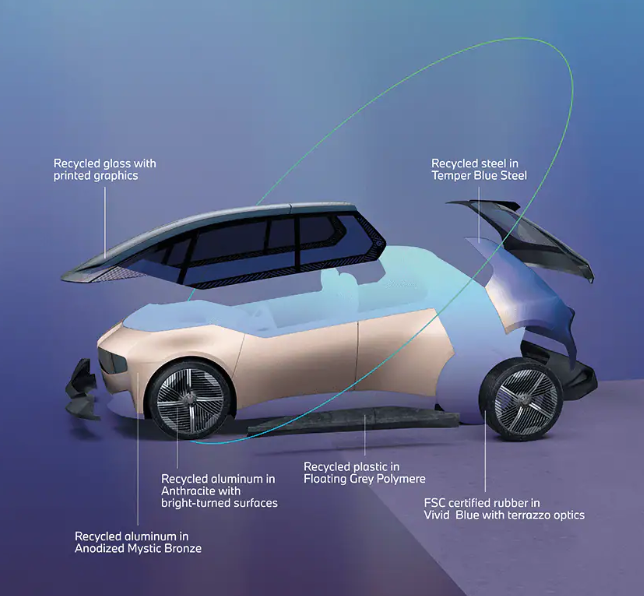

Another example is The BMW i Vision Circular – a fully-electric four-seater with a consistent focus on sustainability and luxury –emblematic of the ambition of the BMW Group to become the most sustainable manufacturer for individual premium mobility. The BMW i Vision Circular is a vision vehicle from the automobile manufacturer BMW and gives a foretaste of the year 2040. The focus of this concept car is on sustainability and luxury. It consistently followed circular economy principles in its design with the intent to reduce CO2 emissions.

3‑4. Figure_ BMW i Vision Circular

[https://www.bmw.com/en/events/iaa2021/bmw-i-vision-circular-domagoj-dukec-first-look.html]

Use of Renewable Raw Materials – ŠKODA, in collaboration with the Technical University of Liberec and the supplier, has developed a sustainable, ecological material made from sugar beet pulp which can be used in dyed form in the interior of vehicles to create certain design accents. In addition, ŠKODA is working on another material based on the miscanthus reed which will also be used in the interior of models in the future [[i]]. The use of rice husks, hemp, cork and coconut fibres is also being researched. ŠKODA is deploying used high-voltage batteries from electric vehicles in stationary energy storage systems before they are recycled. This second life cycle effectively reduces the batteries’ CO2 footprint [29].

The VW Group is investigating the use of other ecologically sourced materials, such as materials based on cellulose.

Toyota has successfully used bio-renewable materials. The car models use the soybean-based polyurethane foam on seats.

[[i]] ŠKODA presents roadmap for sustainable mobility https://skodamedia.com/en-gb/releases/1350