Lesson 7: Circular economy of LIBs

Advancements in lithium ion battery (LIB) technologies have increased the practicality and attractiveness of electrically-driven vehicles (EV), leading to an increase in their development and production, as well as that of LIV. Despite of this, the problem still remains to develop a truly sustainable method of dealing with these batteries at their end-of-life (EOL).

One possibility is to give EOL EV batteries a second life as stationary energy storage.

The term LIB covers a range of different battery chemistries, each with different performance attributes. LIBs are configured in cells, modules, and systems. Battery modules and especially systems need peripheral units such as a temperature and a battery management system.

Depending on the field of application, the design of cells and modules varies considerably. Whereas applications with a smaller battery size often use cylindrical cells due to their dimensions, prismatic cells are primarily used for bigger battery systems, e.g., traction batteries. Pouch cells with an Al composite foil as a casing instead of a rigid Al or steel casing are used among a wide range of applications in order to increase the energy density. In addition, battery systems without module levels are currently under development [[i]].

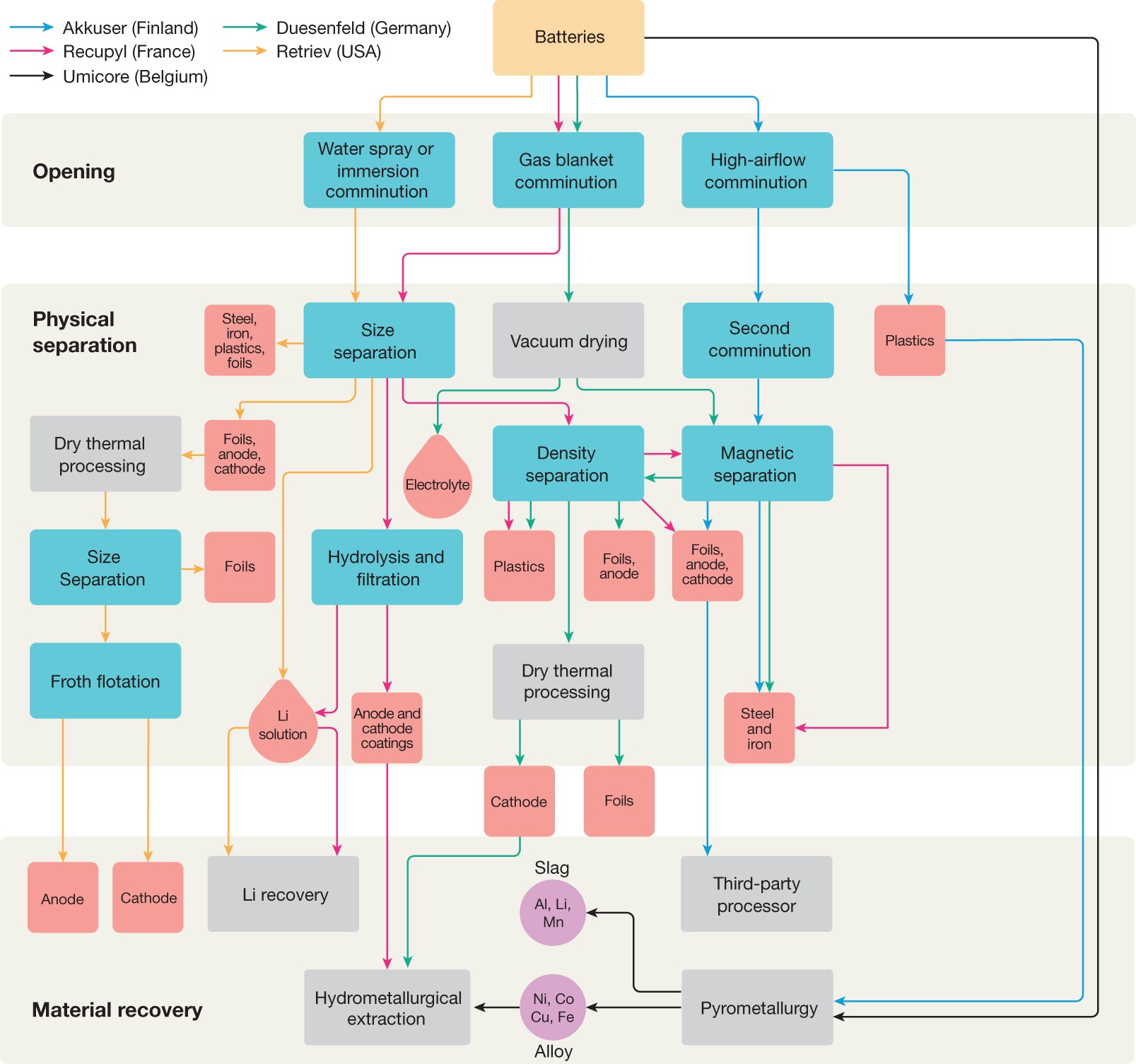

The batteries of electric cars mostly receive a second chance at life after they no longer serve the purpose for which they were built, for example, are used in charging stations on highways or become energy generators for homes. The potential routes for the circular economy of LIBs are pointed out in 5‑2. Figure.

5‑2. Figure_ Flow chart representing potential routes for the circular economy of LIBs, detailing second-use applications, re-use, physical recovery, chemical recovery and biorecovery

[From: Recycling lithium-ion batteries from electric vehicles ]

The material resources used in batteries are limited, and their recovery is essential in the medium and long term. Raw materials such as cobalt, lithium and nickel are key ingredients for lithium-ion batteries. The mining of these materials can present serious ethical and environmental concerns, including reports of child labor, pollution and heavy water use. What’s more, the materials are finite: supply may struggle to meet future demand.

That makes recycling all the more important. Currently, however, the recycling rate for EV batteries is extremely low, with some estimates putting it at five percent. This needs to change for electric mobility to represent a sustainable solution.

The waste-management hierarchy considers re-use to be preferable to recycling. As considerable value is embedded in manufactured LIBs, it has been suggested that their use should be cascaded through a hierarchy of applications to optimize material use and life-cycle impacts. Energy stored over energy invested (ESOI)—the ratio between the energy that must be invested into manufacturing the battery and the electrical energy that it will store over its useful life—is a metric used to compare the efficacy of different energy-storage technologies. Clearly, ESOI figures will improve if end-of-life electric-vehicle batteries can be used in second-use applications for which the battery performance is less critical. Profitable second-use applications also provide a potential value stream that can offset the eventual cost of recycling, and already a healthy market is developing in used electric-vehicle batteries for energy storage in certain localities, with demand potentially outstripping supply.

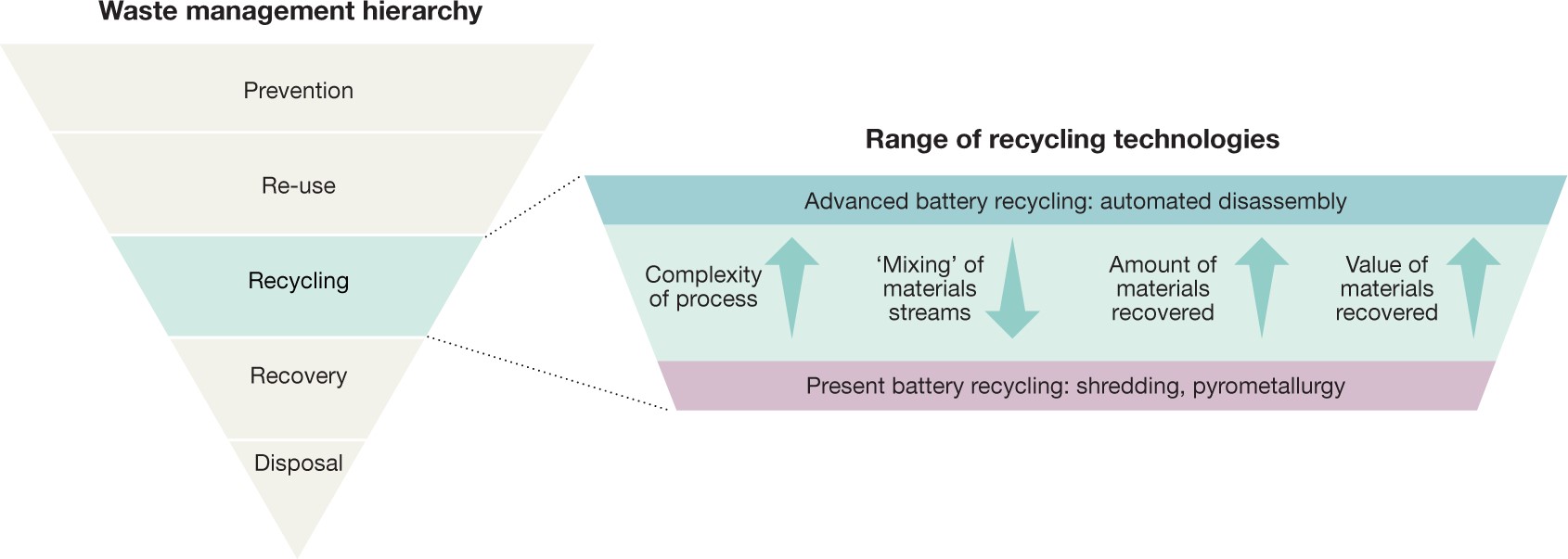

The waste management hierarchy for LIBs is represented in 5‑3. Figure.

5‑3. Figure_ Waste management hierarchy LIBS

[https://doi.org/10.1038/s41586-019-1682-5]

The hierarchy is expanded to consider the range of battery recycling technologies.

Prevention means that LIBs are designed to use less-critical materials (high economic importance, but at risk of short supply) and that electric vehicles should be lighter and have smaller batteries to prevent and reduce waste generation.

Re-use means that electric-vehicle batteries should have a second use to extend their service lifetime.

Recycling means that batteries should be recycled, recovering as much material as possible and preserving any structural value and quality (for example, preventing contamination).

Recovery means using some battery materials as energy for processes such as fuel for pyrometallurgy to recover energy from waste.

Disposal means that no value is recovered and the waste goes to landfill.

[[i]] Brückner L, Frank J, Elwert T. Industrial Recycling of Lithium-Ion Batteries—A Critical Review of Metallurgical Process Routes. Metals. 2020; 10(8):1107. https://doi.org/10.3390/met10081107