Lesson 5 – Automotive plastic waste recovery

The role of plastic in the design and manufacturing of automotive vehicles has become essential, with strict regulations driving demand for more affordable, lightweight, and fuel-efficient vehicles.

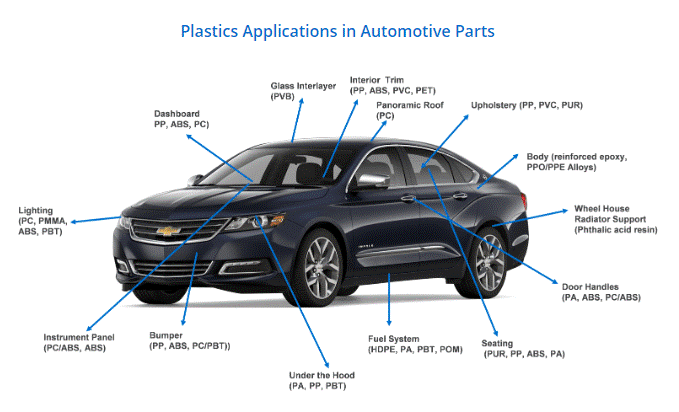

Currently, there are about 30,000 parts in a vehicle, out of which 1/3 are made of plastic. In total, about 39 different types of basic plastics and polymers are used to make an automobile. More than 70% of the plastic used in automobiles comes from four polymers: polypropylene, polyurethane, polyamides and PVC.

Plastic has become one of the key materials required for the structure, performance, and safety of automobiles in recent years, with growth in plastic consumption being driven by light weighting trends for fuel efficiency and consequently lower greenhouse gas emissions. The high absorption properties of plastics also allow the vehicle to meet stricter safety standards, while the use of engineering plastics allows for the minimization of the mass of parts used in vehicles as they offer more design freedom compared to metals [[i]].

3‑1. Figure_ Plastics applications in automotive parts

[http://adapt.mx/plastics-in-the-automotive-industry-which-materials-will-be-the-winners-and-losers/]

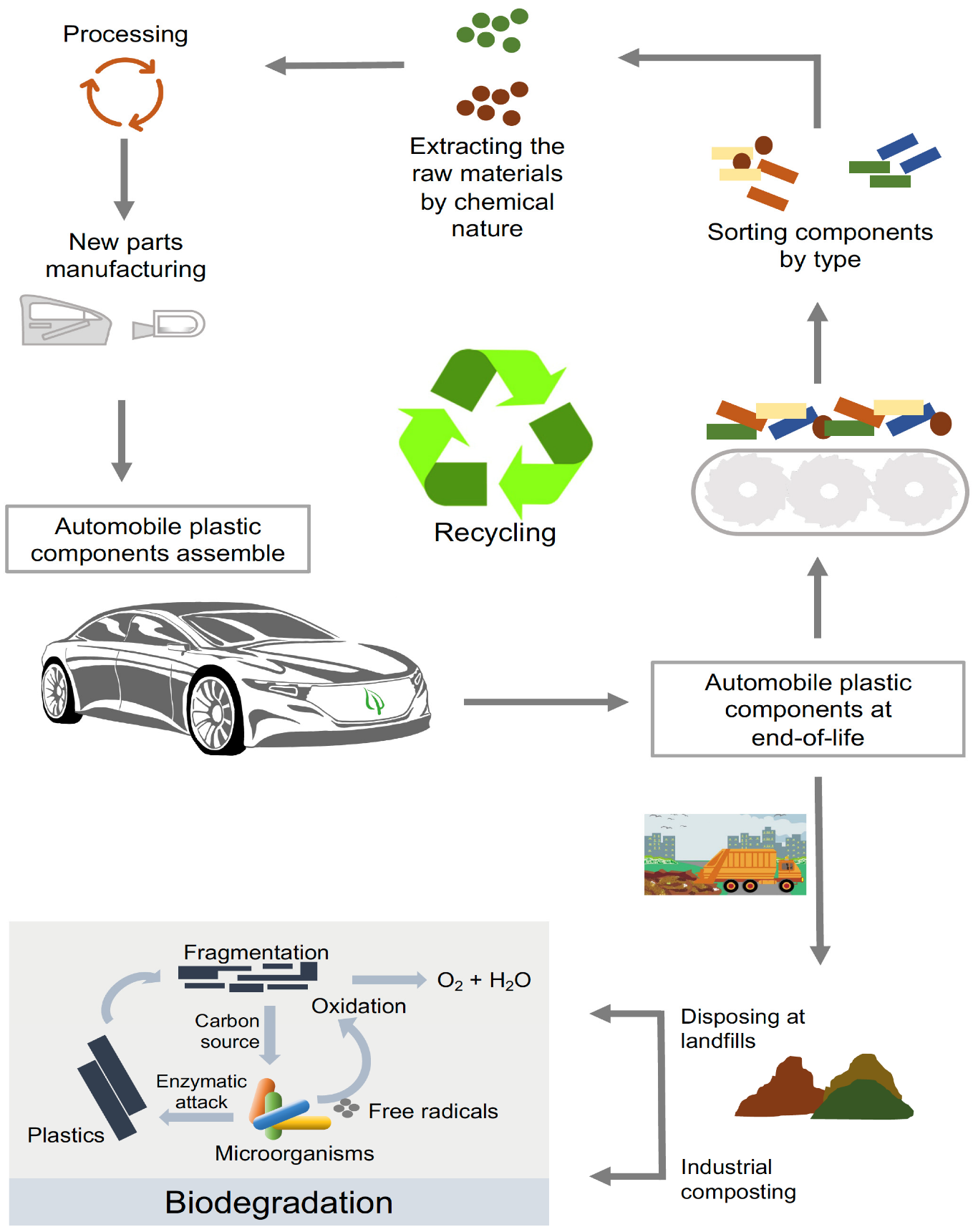

Engineering and conventional plastics, also termed fossil-derived plastics, are not biodegradable by microorganisms within a reasonable time frame. Generally, it would take about 300 years for 60 mm of some plastic films to degrade entirely in soil; this is why plastics are considered an ecological problem [[i]]. A great amount of the plastic waste components are still treated as “waste,” and there is a significant opportunity to recycle more of the plastics used in the automotive sector.

Factors that currently limit mechanical recycling include: contamination issues, technical challenges of separating resins in mixed resin products, and lack of markets for some plastics. While technically all thermoplastics can be recycled, the conditions identified above can make recovery through mechanical recycling economically impossible. The result is that many plastics still are not recovered at end-of-life.

Figure 3‑2 Automobile bioplastic components disposal at end-of-life [https://doi.org/10.3390/polym14163412]

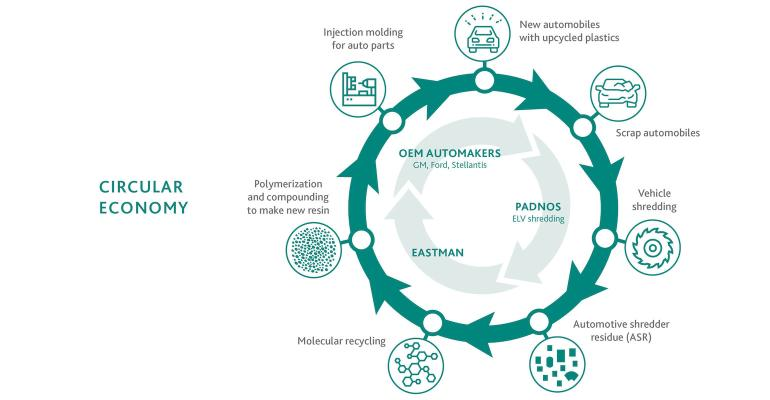

Example: Innovative plastic recycling using a by-product of shredded end-of-life vehicles

Eastman has announced the successful completion of its closed-loop recycling project for automotive mixed plastic waste. Through a collaborative effort, Eastman, the United States Automotive Materials Partnership LLC (USAMP), automotive recycler Padnos, and global automotive interior supplier Yanfeng demonstrated first-of-its-kind plastic recycling using a by-product of shredded end-of-life vehicles [[i]].

3‑3. Figure_Closed-loop recycling of automotive mixed plastic waste

Some recycled plastics are in use in the automotive industry:

- The Karlsruhe Institute of Technology (KIT) and Audi launched a pilot project for recycling plastics in 2020. The no-longer-needed plastic parts, such as fuel tanks, decorative wheel trims, or radiator grilles from Audi models, are turned into pyrolysis oil through chemical recycling. The quality of this oil equals that of petroleum products, with the materials made from it offering the same high quality as new goods. The objective is to create new automobile parts from this pyrolysis oil.

- Ford announced progress towards using 20% renewable and recycled plastics by 2025.

- In their 2030 milestone program, Toyota envisions establishing 30 plants for the appropriate treatment and recycling end-of-life vehicles.

[[i]] https://www.plasticstoday.com/automotive-and-mobility/closed-loop-recycling-automotive-mixed-plastic-waste-deemed-success

[[i]] Vieyra, H.; Aguilar-Méndez, M.A.; San Martín-Martínez, E. Study of biodegradation evolution during composting of polyethylene-starch blends using scanning electron microscopy. Journal of Applied Polymer Science 2013, 127, 845–853. [Google Scholar] [CrossRef]

[[i]] http://adapt.mx/plastics-in-the-automotive-industry-which-materials-will-be-the-winners-and-losers/